The completely green outerwear by Madex SRL

KI-72 is designed and studied in Italy with a sustainable concept

KI-72 Project: sustainable Outerwear

Born from a successful experience in the outerwear industry, KI-72 is a capsule that combines sustainable materials innovation with quality and style.

KI-72 it’s the first pilot study that concentrates the attention on the effort that are being made at a global level in order to lower the polluting processes. KI-72 name origins from a series of microorganisms that have been catalogued as “nylon eater” and discovered during the 70’s.

KI-72 Mission

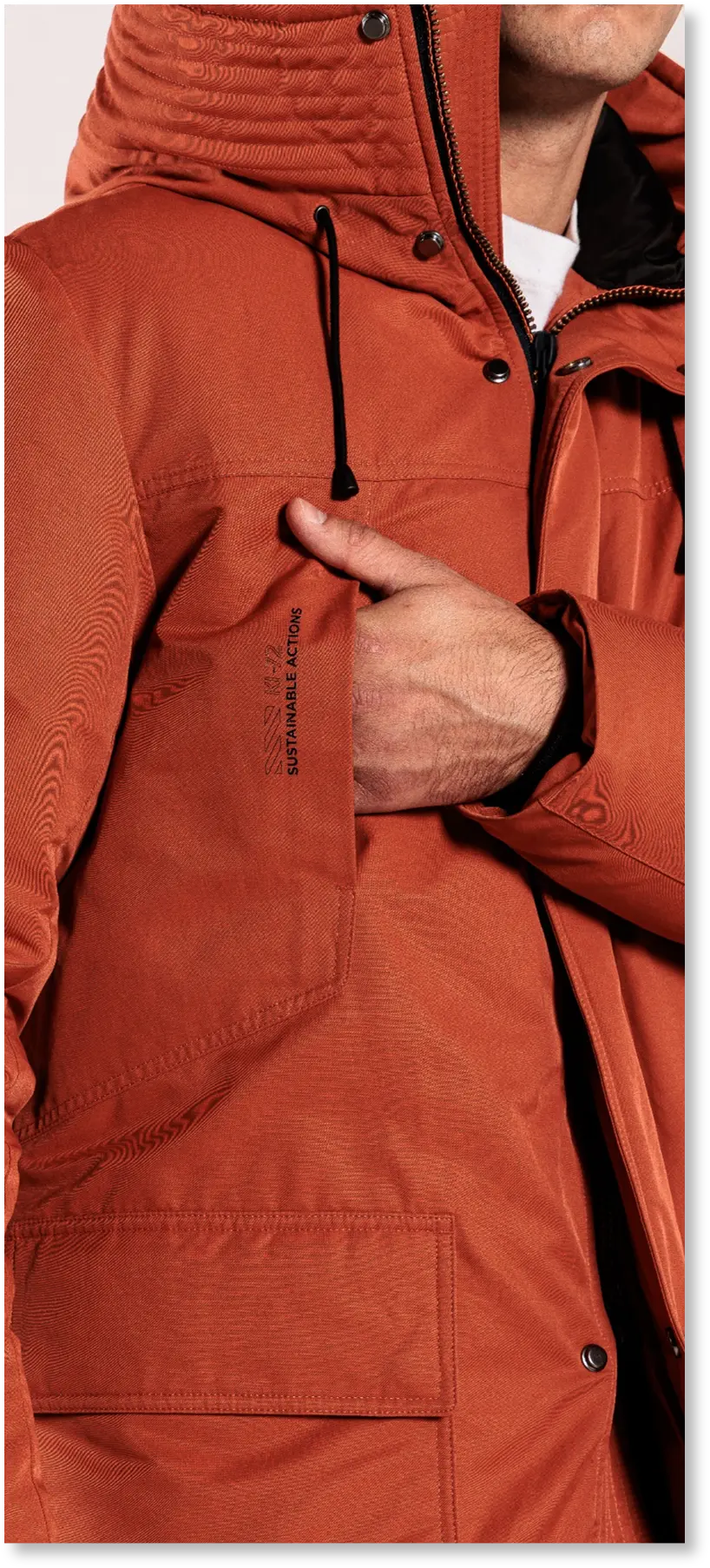

Using the KI-72 Project innovations, Madex wants to show its customers that it is possible to be engaged in lowering the final environmental impact of the outerwear production process, either by looking for recycled and innovative materials or by endorsing the circular use of resources.

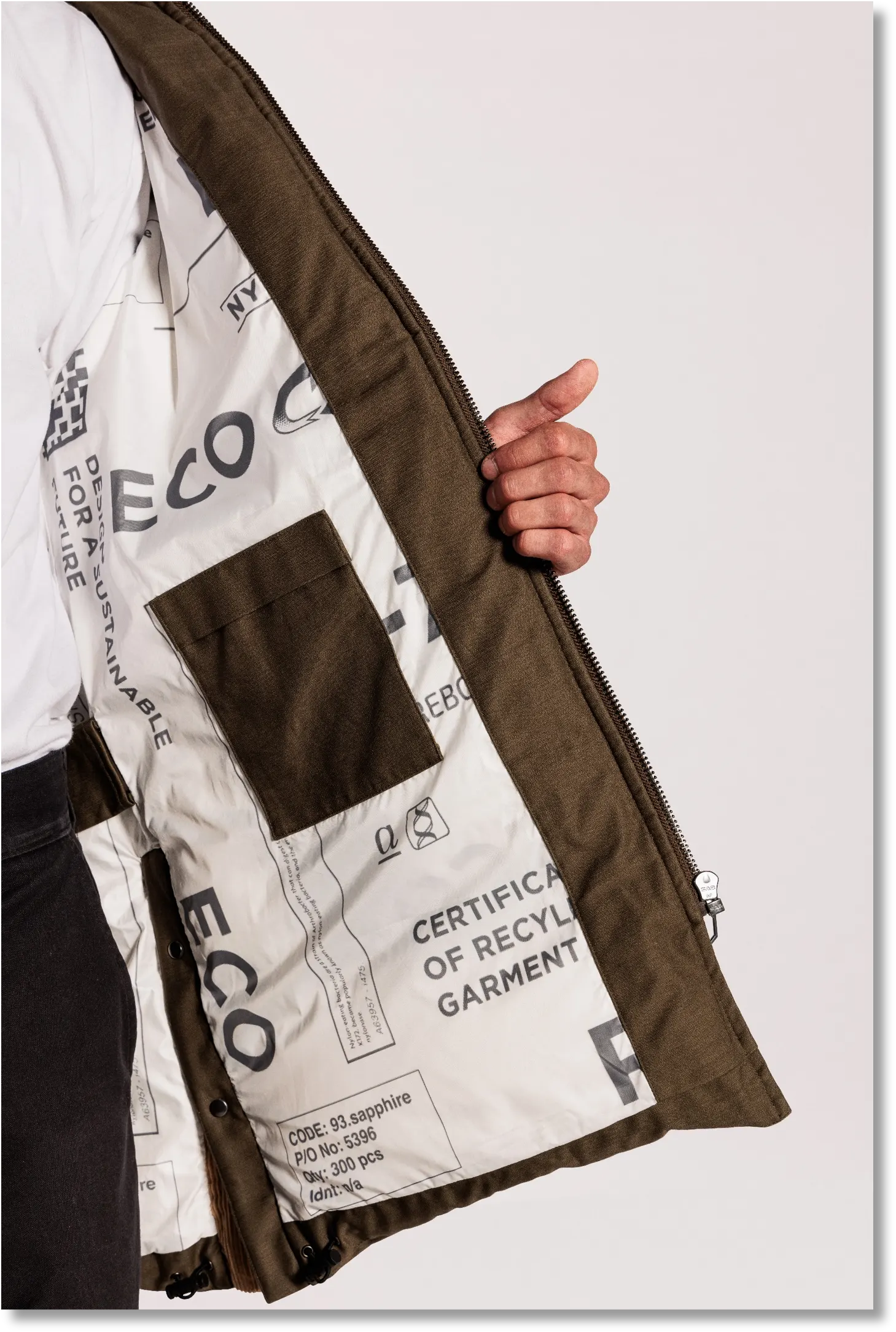

Ethics and transparency are the two keywords for KI-72 Project: all raw materials and the workmanship involved in the collection are granted by the most important international certifications on the sustainable fashion field.

Not just a message

We look around and from what we can clearly see we are not treating our world with the necessary and due respect.

Madex, with KI-72 Project, aims to give its contribution through the choice of “wearing the sustainable” which brings also the outerwear garment to be in line with the very urgent behaviours the nowadays society is asking us to adopt.

KI-72 Collection

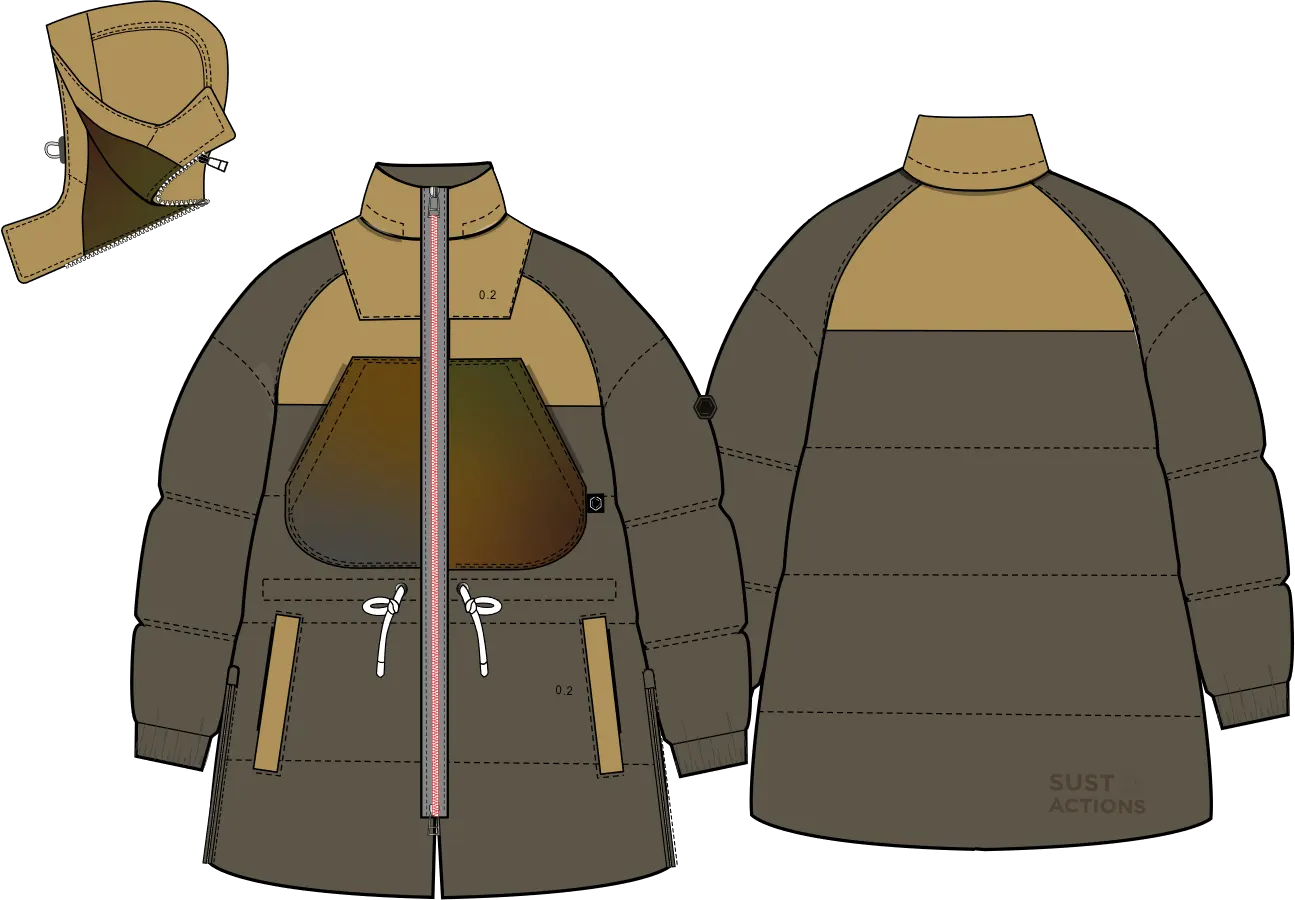

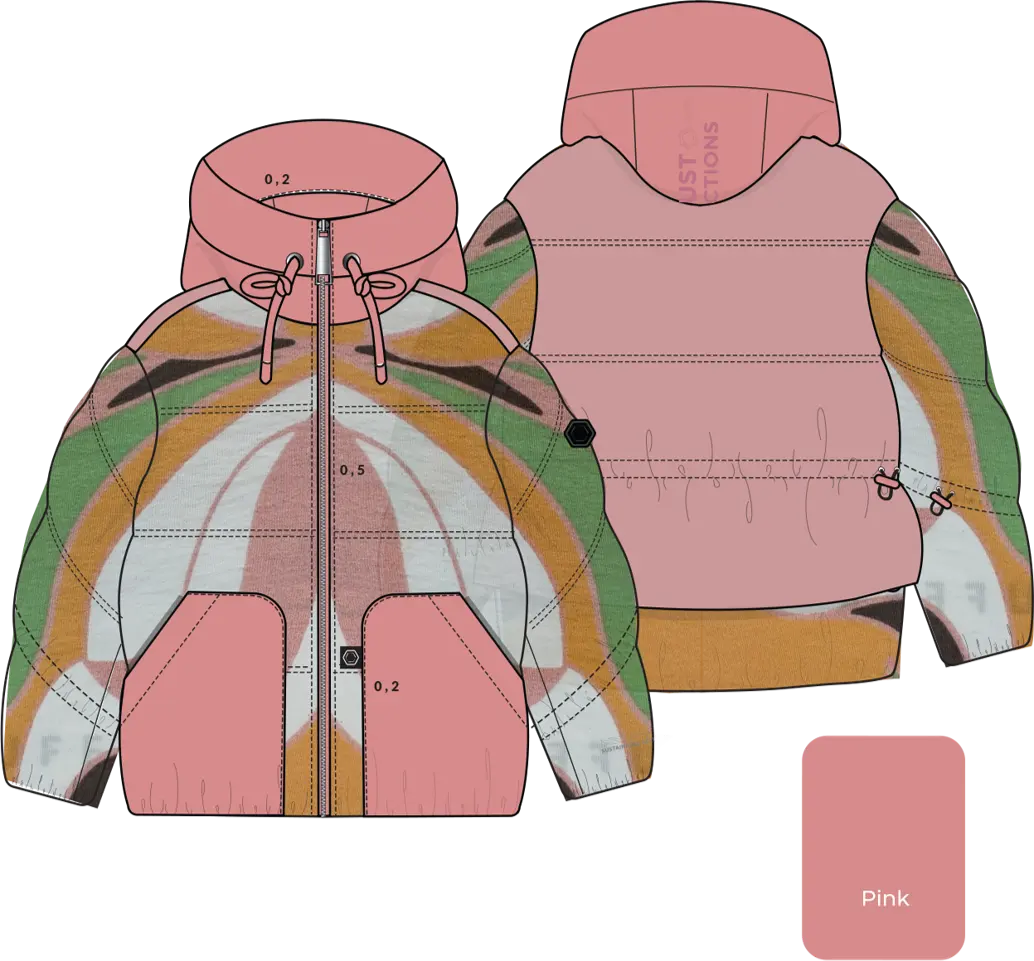

Starting from the garment design Madex, using the KI-72 workshop, projects and manufactures an eco-sustainable outerwear line featuring a Urban Utility look.

All raw materials involved in the process are aligned with KI-72 claim:

Reborn // Bio // Recycle

Yarn

100% Recycled nylon yarn, heavy structure, natural crinkle, water repellent C0 finish PFC free

Lining

Microripstop 100% Recycled nylon from pre-consumer yarn

Trims

Polyester containing a variable percentage ranging from 20% to 50% of natural waste products (mother-of-pearl, horn, minerals, marble powder, cereals, vegetables)

Fabric

Natural fabrics as 100% cotton as based and 60% linen 25% cotton 15% lyocel corduroy for contrasts

Lining

100% Recycled polyester yarn dyed fabric from used garments reborn (Eco Circle)

Trims

Elastic drawcord and stoppers in 100% Recycled polyester

Filling

Wool down blend bio: a performance insulation engineered by intimately blending 70% premium European down with 30% Italian Merino wool sourced from Puglia.

Pure White Duck Down 90/10 En Standard (81% Down Cluster), FP 650 CUIN – RDS Certified.

Moisture management – breathable – Animal-friendly – Warm

Printed Fabric

96% Recycled nylon 4% Bio spandex, wrinkle and weft stretch, water repellent C0 finish PFC free

Back Fabric

100% Recycled nylon yarn, glossy brightness down proof, wind proof, water repellent C0 finish PFC free

Contrast Fabric

100% Recycled nylon cotton like, rainproof (water resistant), breathable, water repellent C0 finish PFC free

Filling

New down-alternative insulation, made of an innovative mixture of hollow polyester fibers with advanced thermal properties.

Its main characteristics are bulkiness, breathability, comfort, durability and a feather-like soft touch. It is a revolutionary alternative to natural down, and imitates its appearance.

It is a revolutionary alternative to natural down, and imitates its appearance.

Composition: 100% recycled polyester

Trims

Elastic drawcord recycle

Oval stopper in bioplastic

Trims

Elastic drawcord recycle

Oval stopper in bioplastic

Wool Fabric

Elastic drawcord recycle

100% Biodegradable virgin wool produced using morette wool without the use of chemical products

Contrast Fabric

Elastic drawcord recycle

100% Recycled nylon yarn, classic memory twill structure, piece dyed, water repellent C0 finish PFC free

Trims

4-hole buttons made of naturally charged polyester with a variable percentage of natural waste products

Elastic drawcord and stoppers in 100% Recycled polyester

Filling

The insulation is accurately washed and sterilized again in order to meet the strictest cleanliness standards in the world.

100% sustainable and eco-friendly filling material. It is the result of the union between a careful recycling process and a production chain based on the attempt to prevent waste.

A final product which has the same potential of virgin down in terms of Fill Power and thermal insulation.

Recycle white duck down 90% STD EN 90/10

Contrast Fabric

The buckle is the combination from recovered PET bottles, with E-ULTRA, a coated product resulting from GMO-free corn for industrial use

Quilt fabric

100% Biogreen N20C nylon, plain, water repellent C0 finish PFC free, wind and down proof

Trims

The buckle is the combination from recovered PET bottles, with E-ULTRA, a coated product resulting from GMO-free corn for industrial use

Fabric

58% cotton 42% Biodegradable nylon, wind proof, easy care, breathability, high resistance, water repellent C0 finish PFC free

Lining

100% Biodegradable polyester, water repellent C0 finish PFC free

Filling

The insulation is accurately washed and sterilized again in order to meet the strictest cleanliness standards in the world.

The insulation is accurately washed and sterilized again in order to meet the strictest cleanliness standards in the world.

A final product which has the same potential of virgin down in terms of Fill Power and thermal insulation.

Recycle white duck down 90% STD EN 90/10

Trims

Zipper entirely composed of a sustainable material, a polyamide with enhanced biodegradability.

Its special composition makes it easier for bacteria to reach and digest the discarded material, thus accelerating the biodegradation process under anaerobic landfilling conditions. It decomposes into organic matter (biomass) and biogas which help to provide new resources for the environment, as well as to produce energy from waste.

Sewing Thread

Si tratta di un filato a biodegradabilità accelerata in Poliammide. L'innovazione del polimero è quella di degradare in circa 5 anni in ambiente anaerobico, testata secondo lo standard internazionale ASTM D5511. Un filato ritorto resistente ed elastico.

Fabric

100% Biodegradable polyester, water repellent C0 finish PFC free

Filling

The fiber used helps to reduce the long-term impact of microplastics in our oceans, landfills and waterways. Products made by these fibers have been specifically developed to return to materials found in nature, in an effort to reduce the environmental impact of microfibers and garments throughout their life.

The innovation lies in the composition of the fibers, which has led to the creation of the world's first 100% recycled, synthetic, and biodegradable fabric.

These fibers break down at a highly-accelerated rate in landfills, oceans and wastewater because we’ve optimized them to be more appetizing to the naturally-occurring microbes in these specific environments.

These microbes enable synthetic insulation and fabric to return to materials found in nature, leaving behind components like water, CO2, methane, biomass and humus – a common, natural component of potting soil.

Fabric

Microripstop 100% Recycled nylon from pre-consumer yarn

Contrast Fabric

3L 100% polyester two way wide stretch + eco-friendly film membrane + 100% Recycle polyester single jersey

Filling

100% Recycled polyester post consumer certificate, an innovative material derived from used plastic bottles.

100% Recycled polyester post consumer certificate, an innovative material derived from used plastic bottles.

The result of the processing is a sustainable fiber, a versatile material that can be used for the production of different types of products.